In the realm of heavy construction and marine engineering, material failure is not an option. Therefore, selecting timber with exceptional density and structural integrity is paramount. While oak and maple are standards in the Northern Hemisphere, they pale in comparison to the density of tropical hardwoods. Specifically, the hardest African woods offer unrivaled durability for the most demanding industrial applications.

African timber species are renowned globally for their mechanical strength. Consequently, importers and contractors turn to these species when projects require longevity under extreme stress. From railway sleepers to hydraulic fenders, these timbers stand the test of time. This guide analyzes the top African species based on the Janka hardness scale.

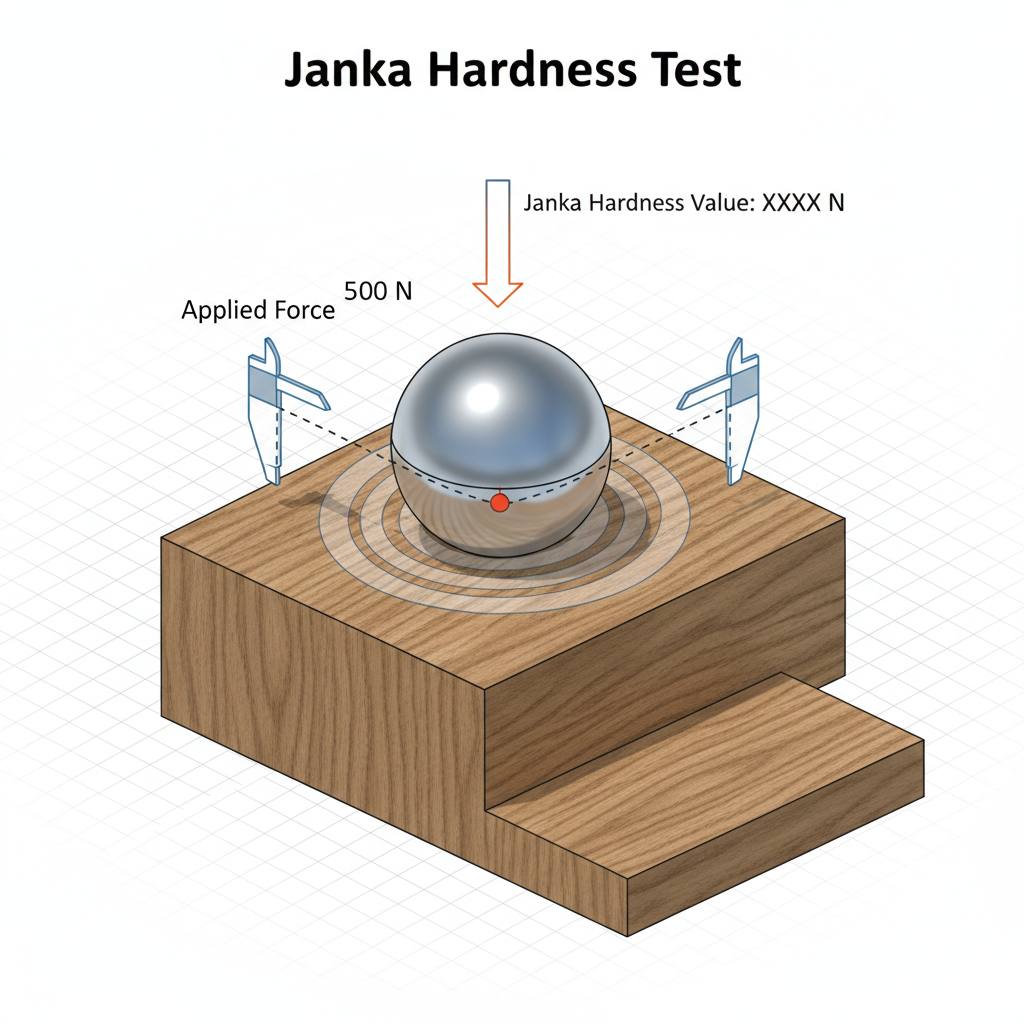

Understanding the Janka Hardness Test

Before diving into specific species, it is crucial to understand the metric used for evaluation. The Janka hardness test measures the resistance of a sample of wood to denting and wear. Specifically, it measures the force required to embed an 11.28-millimeter diameter steel ball halfway into a sample of wood.

For construction professionals, this number is more than trivia. It indicates how well a timber surface will resist scratching, indentation, and general wear. Moreover, high Janka ratings often correlate with higher density and rot resistance. Therefore, understanding this scale is essential for procurement in industrial projects.

Top 5 Hardest African Woods for Heavy Construction

Africa produces some of the densest commercially available timber in the world. We have selected the following species based on their availability for export and their superior mechanical properties. These woods consistently outperform domestic species in load-bearing capacity and weather resistance.

1. Azobé (Ekki) – The Ironwood of Africa

Scientific Name: Lophira alata

Janka Hardness: ~3,350 lbf (14,900 N)

Azobé, often referred to as Ekki, is arguably the most significant timber for marine engineering. It is incredibly dense and sinks in water. Furthermore, its interlocked grain provides massive structural strength. Because of its high silica content, it is naturally resistant to marine borers and termites.

Contractors favor Azobé for hydraulic works, bridge planking, and lock gates. It does not require chemical treatment, which makes it an environmentally friendly option for waterways. However, its hardness requires carbide-tipped tools for processing.

2. Tali (Sasswood) – The Durable Workhorse

Scientific Name: Erythrophleum ivorense

Janka Hardness: ~2,920 lbf (13,000 N)

Tali is a powerhouse in the African timber market. It offers a golden-brown to reddish-brown hue that darkens with age. More importantly, it possesses excellent weathering properties. Consequently, it is frequently used in heavy external decking and railway sleepers.

The wood is highly stable once dried. In addition, Tali is resistant to acids, making it suitable for industrial flooring in chemical plants. For detailed technical data on Tali, reliable sources like The Wood Database provide comprehensive shrinkage values.

3. Bilinga (Opepe) – The Vibrant Structural Choice

Scientific Name: Nauclea diderrichii

Janka Hardness: ~1,630 lbf (7,250 N)

While slightly softer than Azobé, Bilinga is still significantly harder than White Oak. It is instantly recognizable by its vibrant orange-yellow color. This species is exceptionally durable against fungal decay. Therefore, it is a preferred choice for piling and harbor works in tropical climates.

Bilinga responds well to sawing, though its interlocked grain can cause blunting. It holds screws and nails well, provided that pre-drilling is performed. This makes it a versatile option for boardwalks and heavy carpentry.

1-1-1024x1024.jpg)

4. Bubinga – The Decorative Giant

Scientific Name: Guibourtia spp.

Janka Hardness: ~2,410 lbf (10,720 N)

Bubinga is unique because it bridges the gap between aesthetic beauty and brute strength. It is often sold as a luxury veneer. However, its massive logs allow for large slab tables and heavy-duty architectural features. The wood is dense, fine-grained, and finishes to a high luster.

Despite its decorative appeal, its high strength-to-weight ratio makes it viable for tool handles and specialty manufacturing. Importers should note that certain Bubinga species are listed under CITES Appendix II, requiring specific export permits.

5. African Padauk – The Stable Foundation

Scientific Name: Pterocarpus soyauxii

Janka Hardness: ~1,970 lbf (8,760 N)

Padauk is famous for its striking reddish-orange color. Yet, its engineering properties are equally impressive. It is renowned for exceptional stability. Consequently, there is minimal movement in service, making it ideal for precision joinery and heavy-duty flooring.

It resists termites and decay remarkably well. For general construction, it offers a balance of workability and hardness that is hard to beat.

Comparative Data: Hardness and Density

To assist procurement managers in making informed decisions, we have compiled the technical data below. This table compares the hardest African woods against common domestic benchmarks.

| Commercial Name | Botanical Name | Janka Hardness (lbf) | Avg. Dried Weight (kg/m3) | Primary Use |

|---|---|---|---|---|

| Azobé (Ekki) | Lophira alata | 3,350 | 1,125 | Marine Construction |

| Tali | Erythrophleum ivorense | 2,920 | 910 | Bridge Decking |

| Bubinga | Guibourtia spp. | 2,410 | 890 | Architectural / Heavy Use |

| Wenge | Millettia laurentii | 1,930 | 880 | Heavy Flooring |

| African Padauk | Pterocarpus soyauxii | 1,970 | 745 | Precision Joinery |

| White Oak (Reference) | Quercus alba | 1,360 | 755 | Standard Construction |

Processing Challenges for Contractors

Working with high-density timber presents specific challenges. First, the blunting effect on cutting edges is severe. Therefore, we recommend using Stellite-tipped bandsaws or tungsten carbide tools for all machining operations.

Second, pre-drilling is mandatory. Attempting to drive nails or screws directly into Azobé or Tali will result in snapped fasteners or split timber. Furthermore, gluing requires careful preparation. Because these woods are often oily or extremely dense, wiping the surface with a solvent prior to gluing is advisable.

Finally, weight must be calculated accurately during logistics planning. A container of Azobé logs will reach weight limits far faster than a container of Okoume. Consequently, freight calculations must be adjusted to avoid overload penalties.

Sustainability and Legal Compliance

Sourcing African hardwood requires strict adherence to international laws. YYW Timber is committed to sustainable forestry practices. We ensure that all our exports comply with local forestry codes and international regulations.

For species listed under CITES (such as certain Bubinga varieties), we provide all necessary CITES export permits. In addition, we verify the chain of custody to prevent illegal logging. Organizations like the ATIBT (International Tropical Timber Technical Association) provide guidelines that we strictly follow.

Importers should always request Certificate of Origin and Phytosanitary Certificates. These documents guarantee that the timber is legally harvested and free from pests. This transparency is vital for maintaining a clean supply chain in the global market.

Why Choose YYW Timber?

We specialize in B2B exports of African hardwoods to global wholesalers and factories. Our expertise lies in selecting the right grade for your project, whether it is FAS (First and Seconds) or specific structural grades. We understand that marine engineers cannot risk material failure.

Moreover, our logistics team handles the complexities of shipping from African ports. We ensure your container arrives on schedule and with the correct documentation. If you require the hardest African woods for your next major project, we are your reliable partner.

Do not compromise on structural integrity. Contact us today to discuss your specifications and receive a competitive quote.