For factory managers and procurement officers worldwide, sourcing African hardwoods requires strict attention to technical specifications. Among these specifications, moisture content (MC) is arguably the most critical variable. Specifically, the choice between KD vs AD Iroko lumber can determine the success or failure of a manufacturing project. Iroko (Milicia excelsa), often referred to as African Teak, is renowned for its durability and stability. However, its performance is intrinsically linked to how it is dried before export.

Many importers face challenges when deciding between Kiln Dried (KD) and Air Dried (AD) timber. Consequently, understanding the technical differences, cost implications, and stability factors is essential. This guide analyzes the specific moisture content standards for Iroko and advises on the best choice for your supply chain.

The Science of Moisture Content in African Hardwoods

Wood is a hygroscopic material. This means it absorbs and releases moisture from its surrounding environment. Therefore, the goal of drying lumber is to reach an Equilibrium Moisture Content (EMC) suitable for the end-use location. If the wood is too wet, it will shrink as it dries. Conversely, if it is too dry, it may swell in humid conditions.

For high-value species like Iroko, controlling this process is vital. Professional exporters must adhere to international grading rules. For instance, the ATIBT (International Tropical Timber Technical Association) sets specific guidelines for African timber trade. Ignoring these standards can lead to warping, checking, and significant financial loss.

Air Dried (AD) Iroko: Characteristics and Best Uses

Air Drying (AD) is the traditional method of seasoning timber. In this process, sawn timber is stacked with stickers (spacers) to allow natural airflow. Subsequently, nature does the work. This method is cost-effective because it requires no energy consumption for heating. However, it is highly dependent on the local climate in West Africa.

Typically, AD Iroko will achieve a moisture content of 18% to 25%, depending on the season. It is rarely possible to achieve lower moisture levels solely through air drying in tropical climates due to high ambient humidity. Furthermore, the drying process is slow. It can take several months for thick distinct specifications to reach an acceptable AD level.

Risks Associated with AD Lumber

While AD lumber is cheaper, it carries risks for importers in drier climates (such as Europe or North America). If you import AD Iroko with 25% MC into a factory with 10% EMC, the wood will dry rapidly. Consequently, this rapid drying causes stress, leading to end-splitting and bowing. Additionally, AD lumber is not sterilized. Therefore, there is a higher risk of surviving insect larvae or fungal spores compared to heat-treated timber.

Kiln Dried (KD) Iroko: The Gold Standard for Export

Kiln Drying (KD) involves placing the timber in a closed chamber where temperature, humidity, and airflow are strictly controlled by computers. This is the preferred method for high-end manufacturing. For Iroko, specific drying schedules are used to prevent surface checking, as Iroko can be prone to oxidative discoloration if dried improperly.

Standard export-grade KD Iroko usually targets a moisture content of 8% to 12% or 12% to 14%, depending on the client’s requirements. This range ensures the wood is stable immediately upon arrival. Furthermore, the heat involved in the kiln process (often exceeding 56°C) sterilizes the wood. This compliance matches ISPM 15 standards for packaging, although the lumber itself usually requires a phytosanitary certificate.

Advantages for Manufacturers

- Dimensional Stability: KD lumber has already undergone the majority of its shrinkage.

- Immediate Usability: Factories can machine the wood immediately without further acclimation.

- Weight Reduction: Removing excess water reduces shipping weight, potentially lowering freight costs.

- Glue Adhesion: Glues and finishes bond significantly better to dry wood than to wet fibers.

Comparative Analysis: KD vs AD Technical Specifications

To assist procurement officers in making data-driven decisions, we have compiled a comparison of KD vs AD Iroko lumber attributes. This table highlights the trade-offs between cost and quality.

| Feature | Air Dried (AD) Iroko | Kiln Dried (KD) Iroko |

|---|---|---|

| Moisture Content | 18% – 25%+ | 8% – 14% (Targeted) |

| Drying Time | 3 – 6 Months (Weather Dependent) | 2 – 4 Weeks (Controlled) |

| Stability Risk | High (Likely to move in dry climates) | Low (Pre-shrunk and stabilized) |

| Pest Control | Low (Requires chemical treatment) | High (Heat sterilization included) |

| Cost | Lower (Base Material Cost) | Higher (Includes Energy/Processing) |

| Ideal Use | External Construction, Local Use | Furniture, Flooring, Joinery |

As illustrated above, KD lumber offers superior predictability. For a deeper dive into species characteristics, reliable data can be found on The Wood Database. However, understanding the raw data is only half the battle. You must also consider the logistics of transport.

The “Container Rain” Phenomenon

A frequently overlooked aspect of importing AD lumber is “container rain.” When timber with high moisture content is loaded into a steel container and shipped across climatic zones, moisture evaporates from the wood. Subsequently, this moisture condenses on the cool ceiling of the container. Finally, it drips back onto the wood.

This cycle can cause severe water staining, mold growth, and fungal attacks during transit. In contrast, KD Iroko releases minimal moisture inside the container. Therefore, utilizing KD stock significantly mitigates the risk of cargo damage during long ocean freight voyages from Africa to Europe or Asia.

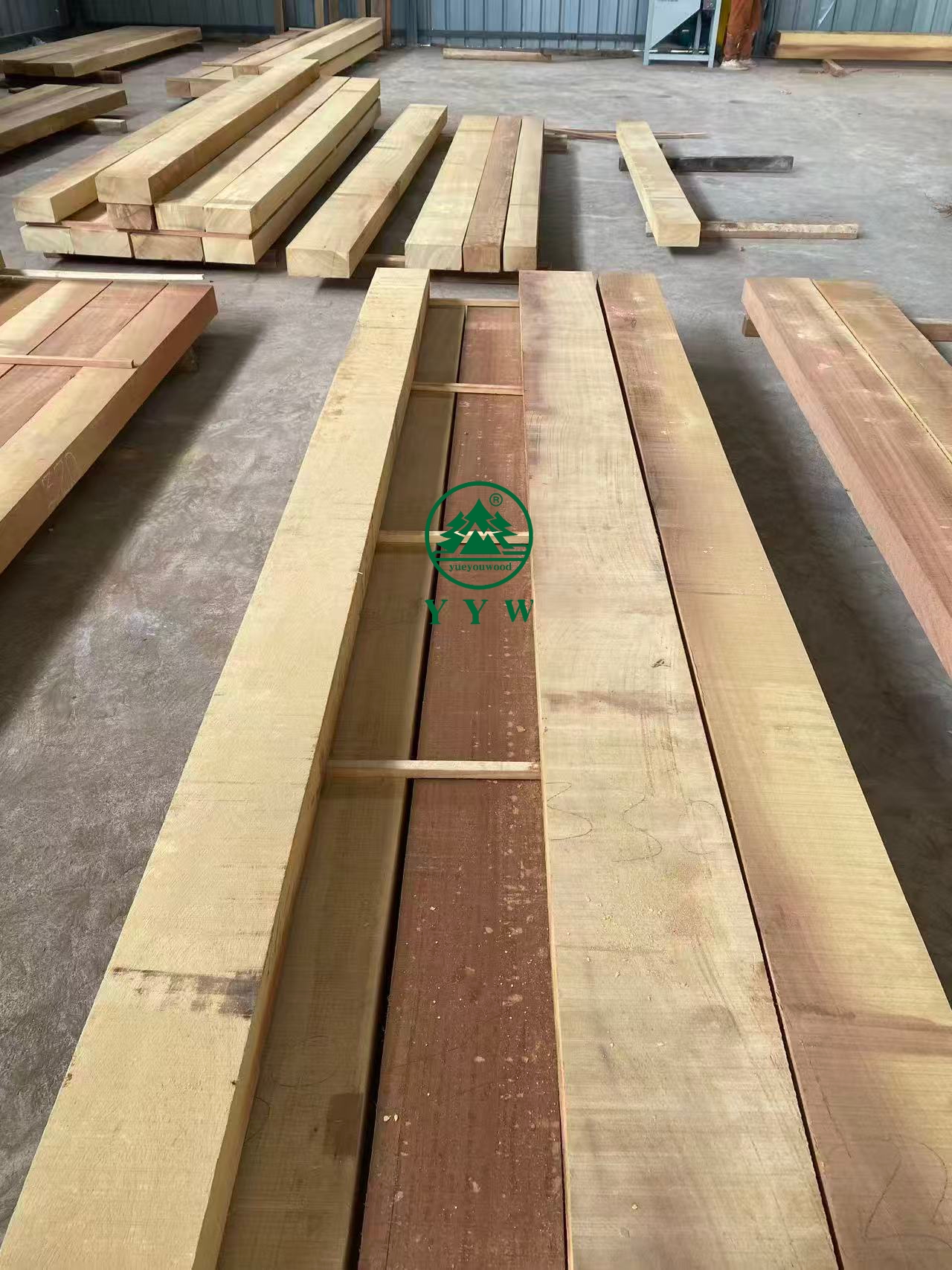

Sourcing Iroko from YYW Timber

At YYW Timber, we prioritize transparency in our processing methods. Whether you require rough sawn timber for further processing or FAS grade lumber for immediate joinery, we adhere to strict drying schedules. Our quality control team measures moisture content at three stages: after sawing, after kiln exit, and immediately before container loading.

We recognize that some large-scale industrial projects may prefer AD timber to reduce initial costs, intending to dry it themselves. In such cases, we ensure the timber is properly stacked and anti-stain treated. However, for most furniture and flooring manufacturers, we strongly advocate for Kiln Dried material. It guarantees a finished product that stands the test of time.

Conclusion: Making the Right Choice

Choosing between KD vs AD Iroko lumber ultimately depends on your manufacturing capabilities and end-product requirements. If you possess your own drying kilns and have time to spare, AD Iroko offers a cost advantage. Nevertheless, for direct-to-production workflows, Kiln Dried Iroko is the indispensable choice to ensure quality and prevent claims.

Ensure your supply chain is secure with legally harvested, correctly dried African hardwoods. Contact our team today to discuss your specific moisture requirements and get a competitive offer.