For high-end joinery factories and interior designers, the quality of raw materials dictates the success of the final project. When sourcing exotic hardwoods like Bubinga, Padauk, or Iroko, the visual appeal is often the primary draw. However, the structural integrity of these woods is equally critical. Consequently, understanding the importance of Kiln Dried Timber becomes paramount for any serious importer.

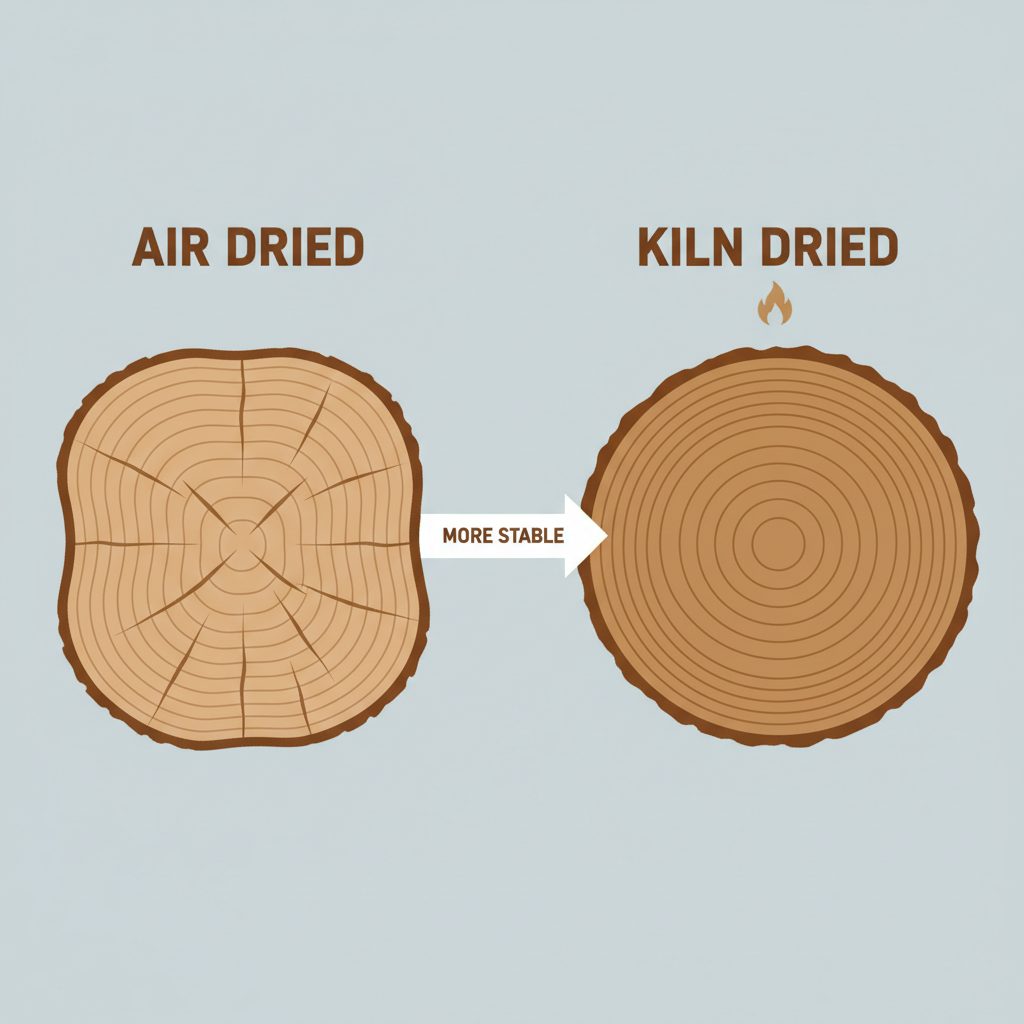

Moisture content is the silent killer of luxury wood projects. If timber is not properly seasoned, it reacts volatilely to changes in humidity and temperature. Therefore, relying on Air Dried (AD) timber for precise indoor applications often leads to disastrous results. In this article, we explore the Kiln Drying (KD) process and why it is the industry standard for stability.

The Science of Wood Stability and Moisture Content

Wood is a hygroscopic material. This means it constantly exchanges moisture with its surrounding environment until it reaches equilibrium. In the dense rainforests of Central Africa, a freshly felled tree can have a moisture content (MC) exceeding 60%. For export and manufacturing purposes, this level must be drastically reduced.

There are two types of water within wood: free water and bound water. Free water resides in the cell cavities, while bound water is held within the cell walls. Removing free water is relatively easy and causes no dimensional change. However, the removal of bound water is where shrinkage occurs. This transition point is known as the Fiber Saturation Point (FSP), typically around 25-30% MC.

To ensure stability in finished furniture or flooring, the timber must be dried below the FSP. Specifically, it should reach an Equilibrium Moisture Content (EMC) that matches the destination’s climate. For European and North American interiors, this target is usually between 8% and 12%. Achieving this precise level naturally is nearly impossible in humid tropical origins; thus, mechanical intervention is necessary.

The Kiln Drying (KD) Wood Process Explained

Kiln drying is a controlled process where temperature, humidity, and air circulation are manipulated to dry timber efficiently. Unlike air drying, which leaves wood at the mercy of the elements, kiln drying offers precision. Furthermore, it sterilizes the wood, eliminating insects and fungi that may be present.

Stage 1: Stacking and Preparation

Before entering the kiln, African hardwood planks are carefully stacked with stickers (spacers) between layers. This spacing is crucial because it allows uniform airflow across every board. Improper stacking can lead to warping before the drying even begins. Consequently, experienced operators at YYW Timber meticulously check sticker alignment.

Stage 2: Heating and Steaming

Initially, the kiln environment is kept humid. Steam is often injected to raise the temperature without drying the surface too quickly. If the surface dries significantly faster than the core, a defect known as “case hardening” occurs. Therefore, the process starts gently, gradually warming the core of the dense African hardwood.

Stage 3: The Drying Cycle

Once the wood is heated through, the humidity is lowered, and the temperature is increased. Fans circulate hot air through the stacks. As the moisture evaporates from the surface, moisture from the core diffuses outward. This phase requires constant monitoring. Species like Tali and Bilinga are extremely dense and require slower schedules to prevent surface checking.

Why Importers Must Prioritize Kiln Dried African Timber

For a joinery factory, the cost of raw material is high, but the cost of failure is astronomical. Using timber that hasn’t been properly kiln dried introduces severe risks to the production line. Here is why investing in KD timber is non-negotiable for high-end applications.

1. Dimensional Stability

When wood dries, it shrinks. If this shrinkage happens after a table has been assembled or a floor installed, the product is ruined. Kiln Dried African timber has effectively been “pre-shrunk” to the dimensions it will hold in service. This stability ensures that joints remain tight and surfaces stay flat.

2. Elimination of Pests

Many importing countries have strict phytosanitary regulations. The heat involved in the kiln process (typically reaching over 56°C for an extended period) is sufficient to kill wood-boring insects and larvae. Consequently, KD timber often passes customs inspections more smoothly than air-dried alternatives.

3. Glue and Finish Adhesion

Modern adhesives and finishes are chemical products designed to bond with wood fibers. However, high moisture levels can inhibit this bonding process. For example, applying a polyurethane finish to damp wood can cause the finish to peel or cloud. Kiln dried stock ensures a receptive surface for premium finishing.

For more technical details on wood density and specific drying properties, reputable resources like The Wood Database offer extensive data profiles.

Comparative Analysis: KD vs. AD Timber

It is important to visualize the differences between Air Dried and Kiln Dried lumber to understand the value proposition. The following table highlights the key metrics relevant to importers and manufacturers.

| Feature | Air Dried (AD) | Kiln Dried (KD) |

|---|---|---|

| Moisture Content | Typically 18-25% | Controlled 8-12% (Export Standard) |

| Drying Time | Months to Years | Weeks |

| Stability Risk | High (prone to movement indoors) | Low (stable in climate-controlled areas) |

| Pest Control | Minimal | High (Heat Sterilization) |

| Ideal Use Case | Outdoor Structures, Fencing | Furniture, Flooring, Interior Joinery |

| Cost Premium | Lower Base Cost | Higher (Energy & Technology costs) |

Navigating the Challenges of Drying Dense Hardwoods

African hardwoods are renowned for their density and hardness. Species like Azobe and Tali are significantly harder than Oak or Maple. This density presents unique challenges during the drying process. Water moves much slower through dense cellular structures. Therefore, aggressive drying schedules can cause honeycomb cracking inside the board, which is invisible from the outside.

To mitigate this, YYW Timber utilizes advanced kiln technologies with variable frequency drives for fans and precise humidity sensors. We monitor the “drying gradient” continuously. Furthermore, we often employ a conditioning phase at the end of the cycle. This step relieves internal stresses (case hardening) that may have developed, ensuring the board doesn’t pinch the saw blade during cutting.

Organizations like ATIBT (International Tropical Timber Technical Association) provide guidelines on grading and drying specific to tropical species, which we strictly adhere to.

Ensuring Quality for Your Import Business

When you order Kiln Dried African timber, verification is key. Simply requesting “KD” is not enough. You should specify the target moisture content relevant to your market. For instance, timber destined for the dry climate of the Middle East may require a lower MC than timber headed to the UK.

- Request Moisture Reports: Ask for data logs from the kiln cycle.

- Verify Stress Relief: Ensure the timber has been conditioned to prevent warping during machining.

- Check Packaging: KD timber should be wrapped or containerized immediately to prevent re-absorbing moisture during transit.

At YYW Timber, we understand that our clients are not just buying wood; they are buying reliability. We control every step of the process, from the forest to the drying chamber. This vertical integration ensures that the Bubinga or Okoume you receive is ready for immediate processing.

Conclusion: The Value of Precision

In the world of international timber trade, precision is the difference between profit and loss. While Air Dried timber has its place in exterior applications, the modern interior market demands the stability that only the Kiln Drying process can provide. By prioritizing Kiln Dried African timber, importers protect their reputation and deliver superior products to their clients.

Do not compromise on the foundation of your manufacturing. Ensure your supply chain is robust, compliant, and technically sound.