Moisture content is the silent killer of timber quality in international trade. For furniture manufacturers and timber importers, the difference between profit and a total loss often hangs on a few percentage points of water. When you import premium African hardwoods like Bubinga, Padauk, or Iroko, precision is non-negotiable. Consequently, knowing how to measure moisture content in timber is a fundamental skill for Quality Assurance (QA) managers.

Incorrect moisture levels lead to warping, cracking, and severe dimensional instability. Furthermore, these defects often manifest long after the wood has left the sawmill. Therefore, accurate measurement serves as your primary defense against costly B2B disputes. This guide outlines professional methods for measuring moisture, tailored specifically for high-density tropical hardwoods.

Understanding Moisture Content (MC) in Tropical Hardwoods

Moisture Content (MC) represents the weight of water in wood as a percentage of the oven-dry weight of the wood fiber. However, African hardwoods present unique challenges due to their density and complex grain structures. For instance, species like Azobe (Ekki) and Tali are extremely dense. Consequently, standard moisture meters may give false readings if not calibrated correctly for Specific Gravity (SG).

There are two critical states of water within the timber:

- Free Water: Liquid water found in the cell cavities. This evaporates first during the drying process.

- Bound Water: Water held chemically within the cell walls. Removal of bound water causes shrinkage.

When measuring, we are primarily concerned with the Fiber Saturation Point (FSP), usually around 25-30% MC. Below this point, the wood begins to change dimensionally. Therefore, for furniture manufacturing, achieving the correct Kiln Dried (KD) status is vital.

Method 1: The Oven-Dry Method (The Gold Standard)

The oven-dry method is the only legally binding way to measure moisture content in timber during arbitration or serious disputes. While slow, it offers absolute precision. This method is outlined in international standards such as ISO 13061-1.

Step-by-Step Procedure

To execute this test accurately, follow these strict protocols:

- Sample Selection: Cut a sample piece from the board. Ideally, cut at least 300mm from the end of the board to avoid end-drying effects.

- Initial Weighing: Immediately weigh the sample. This value is the “Initial Weight” ($W_{wet}$). Precision scales are mandatory here.

- Drying: Place the sample in a ventilated oven at 103°C ± 2°C. Maintain this temperature until the weight stabilizes.

- Final Weighing: Once the weight stops decreasing, record the “Oven-Dry Weight” ($W_{dry}$).

- Calculation: Use the formula below to determine the percentage.

MC % = [ (Initial Weight - Oven Dry Weight) / Oven Dry Weight ] x 100Although accurate, this method is destructive and time-consuming. Therefore, it is typically reserved for calibration checks or resolving formal claims regarding African timber shipments.

Method 2: Resistance Moisture Meters (Pin Meters)

For daily operations and receiving inspections, resistance moisture meters are the industry standard. These devices utilize two pins driven into the wood to measure electrical resistance. Since water conducts electricity and wood acts as an insulator, lower resistance indicates higher moisture. However, simply poking the wood is insufficient for professional QA.

Critical Best Practices for Pin Meters

To ensure data integrity when inspecting a container of Sapele or Okoume, adhere to the following rules:

1. Temperature Corrections

The temperature of the wood affects electrical resistance. Cold timber reads lower, while hot timber reads higher. Consequently, most high-end meters have built-in correction tables. Always measure the wood temperature and input it into your device.

2. Species Correction (Specific Gravity)

African hardwoods vary immensely in density. A meter set for Pine will give disastrously wrong readings for Bubinga. You must adjust the meter settings based on the species’ specific gravity. For reliable density data, refer to The Wood Database before inspection.

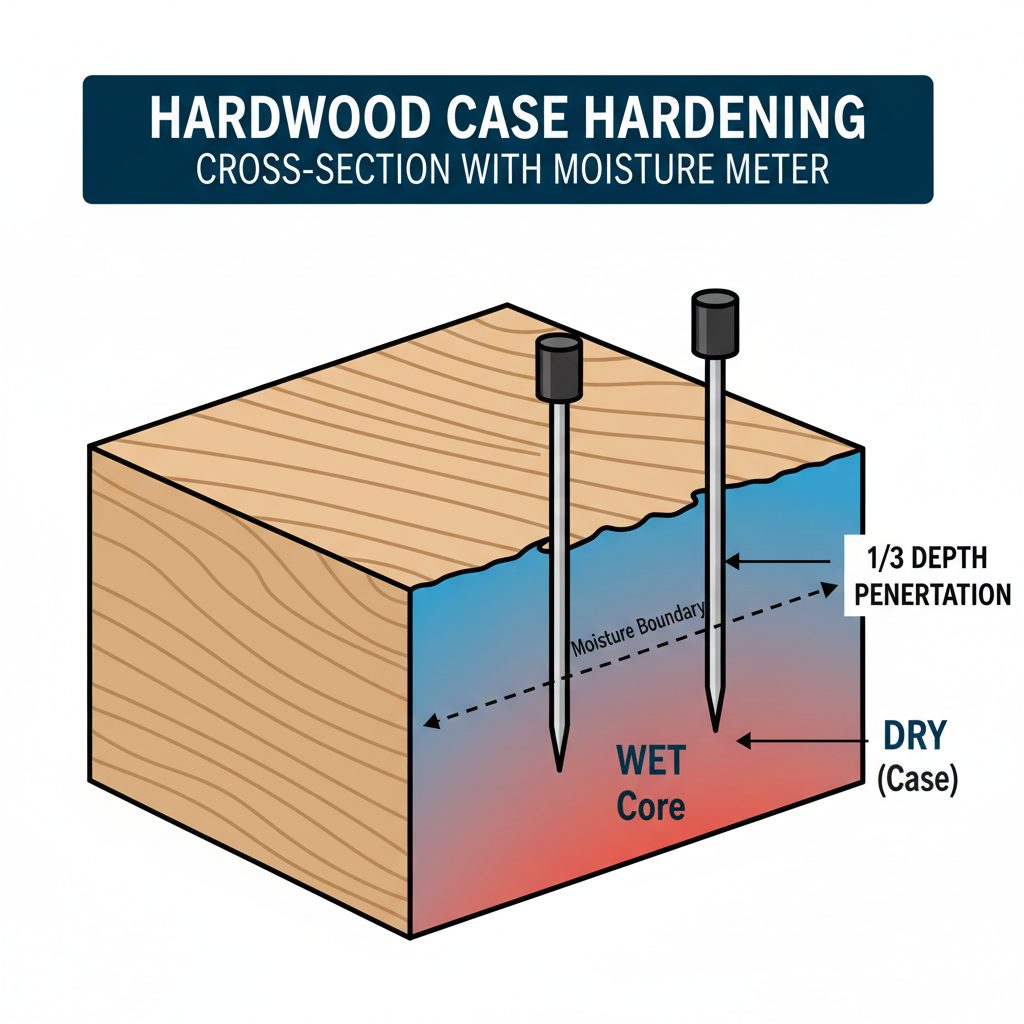

3. Pin Depth Matters

Moisture is rarely uniform. Usually, the core is wetter than the shell (a moisture gradient). To get an average reading, drive pins to 1/4 or 1/3 of the board’s thickness. Furthermore, for thick stock (over 50mm), you should use insulated pins that only read at the tip to detect “wet pockets” in the core.

4. Grain Orientation

Always align the pins parallel to the grain. Measuring across the grain can disrupt the electrical path and provide inconsistent data.

Preventing Quality Disputes: The Contractual Angle

Disputes often arise not because the wood is bad, but because the expectations were mismatched. When importing from YYW Timber or other African exporters, clarity is your ally. Specifically, the moisture content must be defined in the contract relative to the final destination.

Equilibrium Moisture Content (EMC) is the level where wood neither gains nor loses moisture from the air. Ideally, your imported timber should arrive close to the EMC of your factory location. If you import timber at 18% MC into a factory with 6% EMC, the wood will shrink rapidly, leading to defects.

| Destination Region | Recommended MC Range | Common End Use |

|---|---|---|

| Western Europe | 10% – 14% | Joinery, Furniture |

| USA (Northeast/Midwest) | 6% – 9% | Flooring, Cabinetry |

| USA (South/Coastal) | 10% – 12% | Construction, Siding |

| Middle East (Desert) | 7% – 9% | Indoor Furniture |

| Southeast Asia (Tropical) | 12% – 15% | Structural, Outdoor |

Common Pitfalls in African Hardwood QA

Even with good equipment, errors occur. Here are three common mistakes to avoid:

- Surface Moisture Interference: If timber has been sitting in high humidity or rain (even if covered), the surface may be wet while the core is dry. Conversely, pinless meters are very susceptible to surface water errors.

- Ignoring the “Cooling Period”: Timber coming fresh out of a kiln needs to equalize. Measuring hot timber immediately often yields unstable results.

- Statistical Insignificance: Testing one board in a container of 1,000 is useless. You must test a representative sample size. We recommend testing at least 10% of the bundles in a shipment.

Conclusion: Precision Protects Profits

Learning how to measure moisture content in timber is more than a technical requirement; it is a financial safeguard. By utilizing calibrated resistance meters and understanding species-specific density, you can filter out non-compliant stock before it enters your production line. Moreover, understanding EMC ensures you order the correct specifications from your supplier.

At YYW Timber, we adhere to strict kiln-drying schedules and verifiable QA processes. We invite our partners to visit our facilities or request detailed moisture reports with every shipment.