For structural engineers and architects, selecting the correct hardwood species is rarely about aesthetics alone. Instead, the decision hinges on quantifiable physical properties. Iroko density and hardness are the primary metrics that define the suitability of Milicia excelsa for high-stress applications. Often referred to as “African Teak,” Iroko offers a mechanical profile that frequently surpasses its Asian counterpart. This article provides a deep dive into the technical specifications of Iroko, analyzing its specific gravity, Janka hardness rating, and the resulting implications for commercial construction and marine engineering.

Understanding Iroko Density: The Foundation of Strength

Density is the most critical indicator of a timber species’ strength and load-bearing capacity. Specifically, the density of Iroko determines its utility in heavy structural framing and exterior decking. At a moisture content of 12%, the average weight of Iroko is approximately 660 kg/m³ (41 lbs/ft³). However, this value can fluctuate between 640 kg/m³ and 680 kg/m³ depending on the origin of the logs within West Africa.

Furthermore, the Basic Specific Gravity (based on green volume and oven-dry weight) generally sits around 0.55. When adjusted for 12% moisture content, the Specific Gravity rises to approximately 0.66. Consequently, Iroko presents a high strength-to-weight ratio. This characteristic is particularly advantageous for structural beams where dead load must be minimized without compromising integrity.

For global importers, understanding these density figures is also vital for logistics. Accurately calculating the payload of a shipping container requires precise weight-per-volume data. Therefore, knowing that Iroko is significantly denser than species like Okoume allows for optimized freight planning.

The Janka Hardness Rating of Iroko

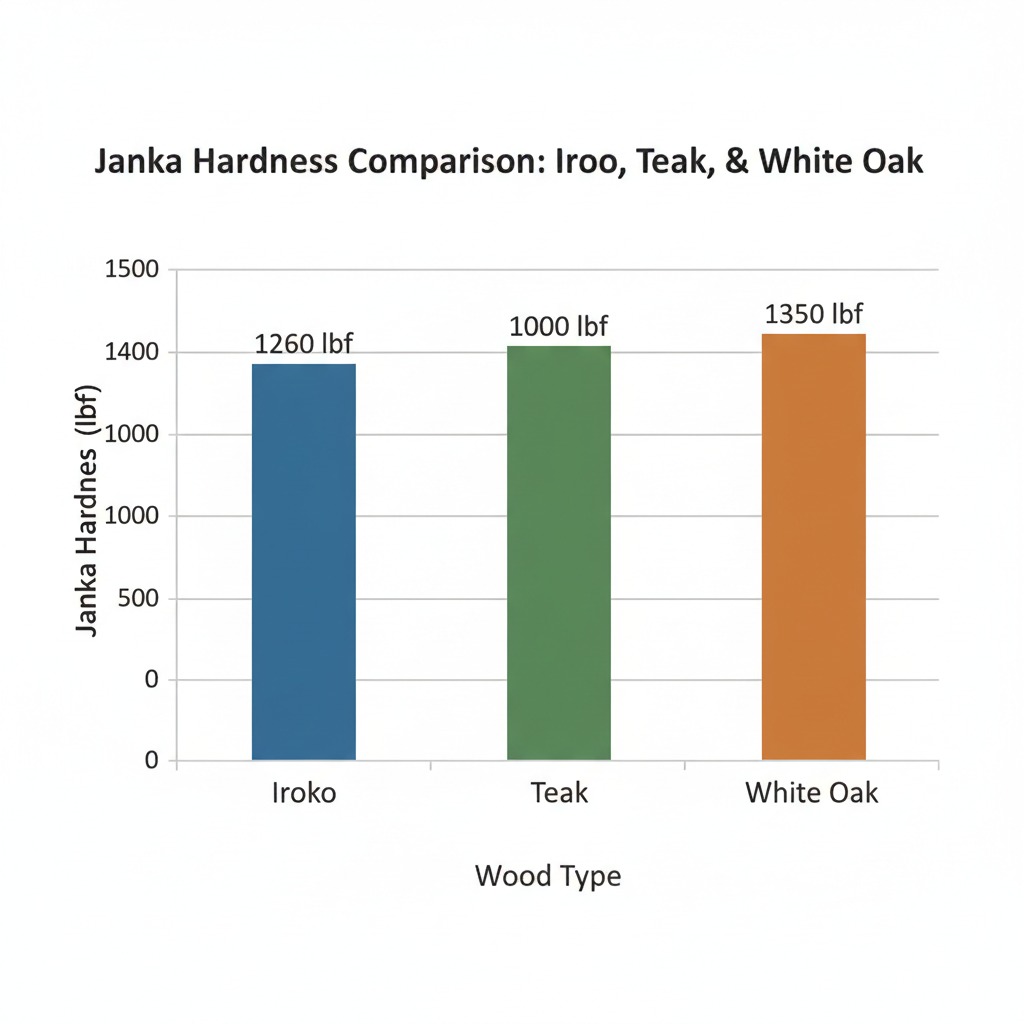

While density dictates weight, the Janka hardness test measures resistance to wear and denting. The Janka hardness rating for Iroko is approximately 1,260 lbf (5,610 N). To put this into perspective, this rating places Iroko slightly above Genuine Teak (Tectona grandis), which typically rates around 1,070 lbf.

This elevated hardness level makes Iroko an exceptional candidate for high-traffic flooring and industrial decking. Because it resists indentation better than many domestic hardwoods, it maintains its surface integrity over decades of use. Moreover, this hardness contributes to the wood’s natural resistance against abrasion. In marine environments, where sand and salt spray act as abrasives, Iroko’s resilient surface proves invaluable.

Nevertheless, this hardness presents challenges in machining. Structural engineers specifying Iroko must account for the necessity of carbide-tipped tools during fabrication. We discuss the nuances of working with this dense timber in our guide on Iroko Sawn Timber processing.

Technical Data Table: Mechanical Properties

For precise engineering calculations, detailed mechanical data is required. The table below outlines the standard physical properties of African Iroko. These figures are essential for calculating beam spans, deflection limits, and load capacities.

| Physical Property | Metric Value | Imperial Value |

|---|---|---|

| Average Dried Weight | 660 kg/m³ | 41 lbs/ft³ |

| Janka Hardness | 5,610 N | 1,260 lbf |

| Modulus of Rupture (MOR) | 87.6 MPa | 12,700 lbf/in² |

| Elastic Modulus (MOE) | 10.76 GPa | 1,560,000 lbf/in² |

| Crushing Strength | 54.0 MPa | 7,840 lbf/in² |

| Radial Shrinkage | 2.8% | 2.8% |

| Tangential Shrinkage | 3.8% | 3.8% |

Structural Stability and Durability

Beyond raw Iroko density and hardness, the stability of the timber is paramount for architects. Iroko is renowned for its low shrinkage values. Specifically, the difference between radial (2.8%) and tangential (3.8%) shrinkage is remarkably small. This low ratio indicates superior dimensional stability.

Consequently, Iroko resists warping, twisting, and cupping when exposed to fluctuating humidity. In large-scale architectural projects, such as cladding or outdoor pavilions, this stability reduces maintenance costs significantly. Furthermore, the heartwood is rated as very durable regarding decay resistance. It is also resistant to termite attack, though not entirely immune in all geographical zones.

Machinability: The Trade-Off of High Density

While the mechanical properties of Iroko are favorable for structure, they complicate the manufacturing process. The high density, combined with interlocked grain, can cause tear-out during planing operations. Therefore, we recommend a cutting angle of 15 degrees to achieve a smooth finish.

Additionally, Milicia excelsa occasionally contains large deposits of calcium carbonate, commonly known as “stone.” These hard mineral deposits can blunt cutter blades almost instantly. Consequently, factories importing Iroko logs or cants must be equipped with specialized tungsten-carbide tooling. Despite these challenges, the resulting surface finish is often lustrous and requires minimal preservation treatment.

Comparing Iroko to Other African Hardwoods

When analyzing Iroko density and hardness, it is helpful to compare it with other regional species. For instance, African Padauk is significantly heavier and harder (approx 1,725 lbf), making it better for heavy-duty flooring but less manageable for general joinery. Conversely, Okoume is much softer and lighter, utilized primarily for veneers and plywood cores.

Iroko strikes a pragmatic balance. It possesses enough density for structural integrity yet remains light enough for efficient handling and installation. This balance establishes Iroko as the versatile “workhorse” of the African timber trade. It serves effectively in boat building, furniture, decking, and veneer simultaneously.

Conclusion: Engineering with Confidence

In summary, the technical profile of Iroko makes it a premier choice for demanding B2B applications. Its specific gravity provides necessary weight for structural stability, while its Janka rating ensures longevity against wear. For importers supplying engineers and architects, offering certified, high-grade Iroko is a strategic move. By understanding the data behind Iroko density and hardness, you can confidently specify this material for projects requiring durability and strength.

Are you looking to secure a reliable supply of structural-grade African hardwoods? YYW Timber provides sustainably sourced, FAS-grade lumber tailored to your specifications.