For decades, genuine Burmese Teak (Tectona grandis) has held the title of the “Gold Standard” in the marine and architectural timber industries. However, shifting geopolitical landscapes, strict export bans in Southeast Asia, and skyrocketing prices have forced procurement officers to seek viable alternatives. Consequently, the global market has turned its eyes toward West Africa. Enter Iroko (Milicia excelsa), frequently marketed as “African Teak.”

For high-volume timber importers and marine contractors, the decision between these two giants is no longer just about aesthetics. It is a calculation of margin, availability, and technical performance. While Teak remains a luxury asset, Iroko has emerged as the pragmatic industrial choice. This analysis explores the technical nuances of Iroko vs Teak to assist wholesalers in making data-driven purchasing decisions.

The Botanical Distinction: Understanding the Species

To understand the market dynamics, we must first understand the wood itself. Teak is native to South and Southeast Asia. It is renowned for its high silica content and natural oils, which provide exceptional weather resistance. However, the supply of old-growth Teak has dwindled significantly. Consequently, much of the market is now flooded with plantation Teak, which often lacks the density and ring tightness of the wild-harvested variety.

In contrast, Iroko is native to the tropical regions of Africa, extending from Sierra Leone to Tanzania. It is not botanically related to Teak, yet it mimics many of its properties. Iroko is typically wild-harvested, ensuring large log diameters and mature heartwood. For importers, this means superior availability of long lengths and wide boards, which are increasingly rare in the Teak market.

Technical Performance: Hardness and Durability

Durability is the primary concern for marine contractors and exterior architects. Both timbers are classified as very durable regarding rot resistance. Nevertheless, there are distinct structural differences that affect their application.

Iroko is significantly harder than Teak. According to standard industry testing, Iroko boasts a Janka hardness rating of approximately 1,260 lbf. Conversely, Teak registers lower, at around 1,070 lbf. This makes Iroko more resistant to indentation and physical wear, an essential trait for heavy-traffic decking or industrial flooring. Furthermore, Iroko possesses excellent strength-to-weight ratios, making it a robust candidate for heavy structural joinery.

However, Teak holds a slight advantage in dimensional stability. Its radial shrinkage is remarkably low. Therefore, Teak is less prone to movement during drastic humidity changes. Iroko is also stable but requires careful kiln drying to prevent checking. Once properly seasoned, however, Iroko performs admirably in exterior environments.

Comparative Data: Iroko vs Teak Specifications

The following table outlines the key technical specifications relevant to B2B buyers and engineers.

| Property | Iroko (Milicia excelsa) | Teak (Tectona grandis) |

|---|---|---|

| Origin | West / Central Africa | Southeast Asia / Latin America (Plantation) |

| Janka Hardness | ~1,260 lbf (Harder) | ~1,070 lbf (Softer) |

| Avg. Dried Weight | 660 kg/m3 | 655 kg/m3 |

| Rot Resistance | Very Durable (Class 1-2) | Very Durable (Class 1) |

| Cost Index | $$ (Moderate) | $$$$ (Premium) |

| Oil Content | Moderate | Very High |

The Economic Argument: Price and Availability

This is where the battle of Iroko vs Teak is usually decided for wholesalers. The price disparity between these two species is massive. Genuine Burmese Teak has become a boutique item, often fetching prices three to four times higher than Iroko. This price surge is driven by scarcity and international sanctions on Myanmar timber exports.

Iroko, available through reputable exporters like YYW Timber, offers a far more attractive ROI. For large-scale projects such as municipal boardwalks, resort decking, or mass-produced outdoor furniture, the cost savings of specifying Iroko are undeniable. You are essentially purchasing Class 1 durability at a fraction of the cost of Teak.

Moreover, availability is consistent. We can source Iroko sawn timber in FAS grade with reliable lead times. In contrast, sourcing large volumes of high-grade Teak can be a logistical nightmare involving long wait times and inconsistent grading.

Workability and Aesthetic Considerations

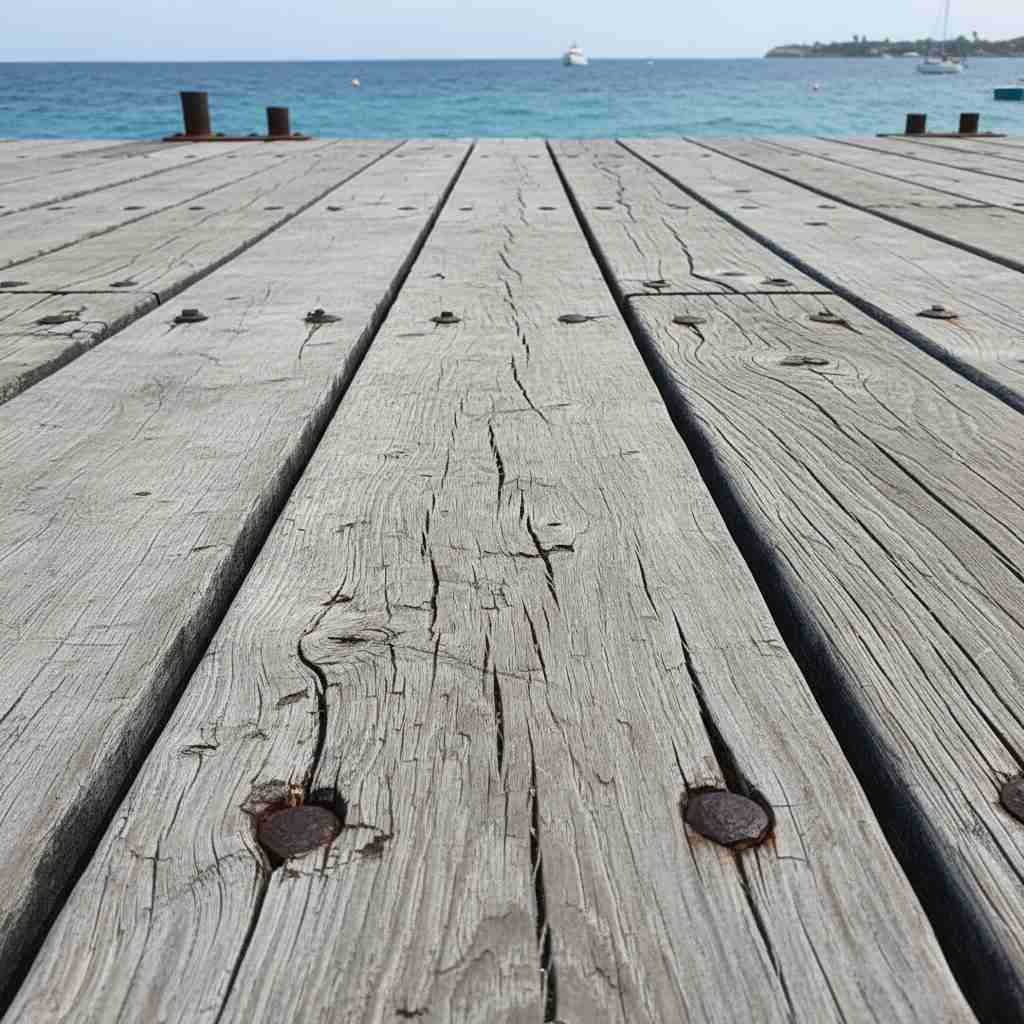

Visually, fresh Iroko starts as a yellow-brown colour. Over time, it undergoes a photo-chemical change, darkening to a rich copper-brown that closely resembles aged Teak. This similarity is why it is the preferred substitute in the architectural world. If left untreated outdoors, both woods will eventually weather to a distinguished silver-grey patina.

However, workability presents a challenge. Iroko often contains interlocking grain. Consequently, machining can sometimes result in tear-out if cutters are not sharp or if the feed speed is incorrect. Additionally, calcium carbonate deposits (stone-like inclusions) are sometimes found in Iroko, which can dull carbide blades. Manufacturers must be aware of this to adjust their tooling accordingly.

Teak is generally easier to work with due to its straight grain, though its high silica content also blunts tools. For a deeper dive into wood properties, reputable sources like The Wood Database provide extensive technical break-downs that confirm Iroko’s competitive standing.

Application Suitability: When to Switch?

When should a wholesaler recommend Iroko over Teak? Here are the primary use cases:

- Marine Decking: While Teak is the king of superyachts, Iroko is the standard for workboats, ferries, and mid-range cruisers. It withstands saltwater exposure exceptionally well.

- Exterior Cladding: For large commercial buildings, the cost of Teak is prohibitive. Iroko provides the same biological resistance and aesthetic warmth for siding and facades.

- Outdoor Furniture: Manufacturers can maintain high profit margins by using Iroko. It is durable enough to offer long warranties without the premium material cost.

Sustainability and Legal Compliance

In the modern B2B landscape, provenance is everything. The Teak market is currently fraught with legal complexities regarding the origin of the timber. Many importers avoid Burmese Teak entirely to ensure compliance with EU and US trade regulations.

African Iroko, when sourced from responsible suppliers like YYW Timber, comes with verified documentation. We prioritize legality and sustainable forest management practices. It is crucial to verify that your supply chain adheres to international standards. For more information on endangered species regulations, referencing CITES is always recommended, although Iroko is generally less restricted than wild Teak.

Conclusion: The Smart Wholesaler’s Choice

In the debate of Iroko vs Teak, there is no single winner, but there is a clear choice for value. Teak remains a luxury product for specific high-budget applications. However, for the vast majority of commercial and industrial needs, Iroko offers a superior balance of durability, availability, and cost-efficiency.

As a wholesaler, diversifying your stock to include high-grade Iroko ensures you can meet the demands of clients who require “Teak-like” performance without the “Teak-like” price tag. It is the pragmatic solution for the modern timber trade.

Are you looking to secure a reliable supply of African Hardwoods? YYW Timber is your partner in global logistics and quality assurance.